Industrial Coatings Applied to OEM Automotive, Aerospace and Mil Spec Manufactured Parts

Consistency.

Quality.

Reliability.

Maximizing Efficiency for Our Customers with Diverse Capabilities

Robotics Paint Application Systems

Four robotic paint application systems

Robotic systems include a carousel and conveyor

Custom built racks for maximum efficiency

Manual Paint Application

Wet paint booths at four locations

Highly skilled and experienced painters

Ideal for complex or specialized jobs

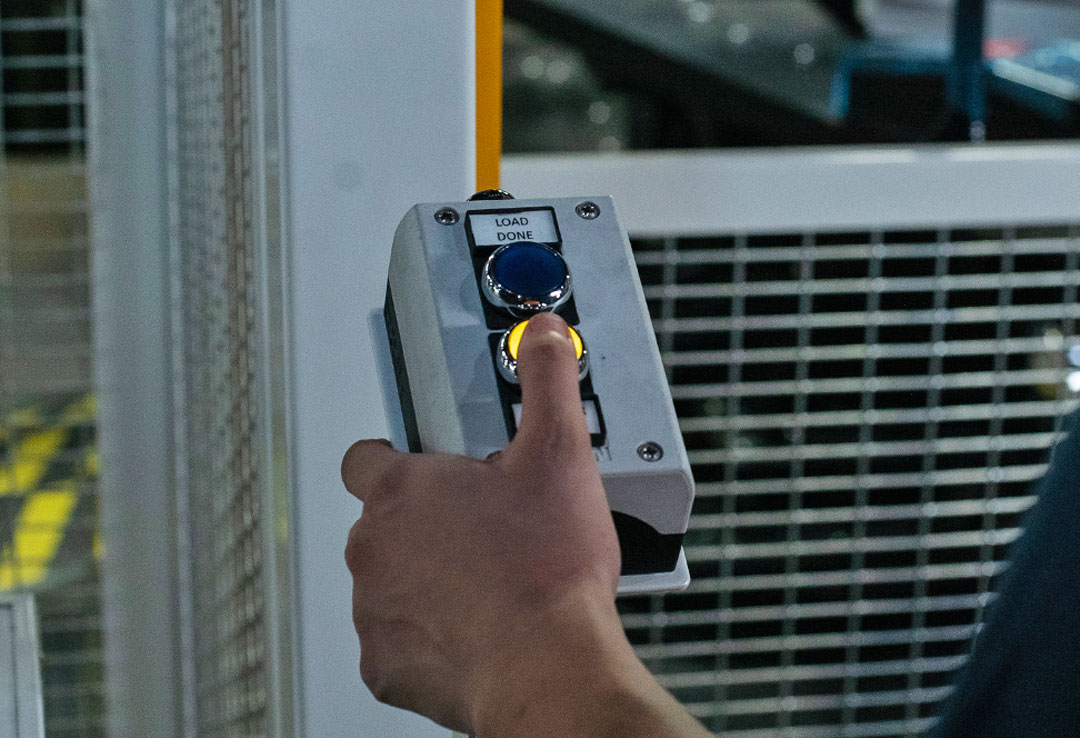

How the Robotic Paint System Works

Parts are racked in a high efficiency pattern on rotating racks

Parts are hand painted. The spray pattern is saved by the robotic software

Robot replicates any spray pattern that has been saved by software

Replicated pattern can be adjusted for maximum efficiency of speed and volume of paint expelled

No Complex Programming Required

Our skilled robotic operators are painting experts. Their painting pattern is instantly mimmicked.

Operators Perform Quality Control Checks

Each robot has a dedicated operator and a continuous quality control protocol.

Our robotic paint systems DELIVER

Reliable quality, at a calculated rate

Trusted day after day by OEM Suppliers

Anodizing Industries is the #1 applicator of Slickote paints and Anodized PTFE sealants

Before & After

Slickote Coating gives the low grade cast-aluminum the appearance of high grade alloy with a durable finish.

Are We the Right Partner for You? View Our Other Services

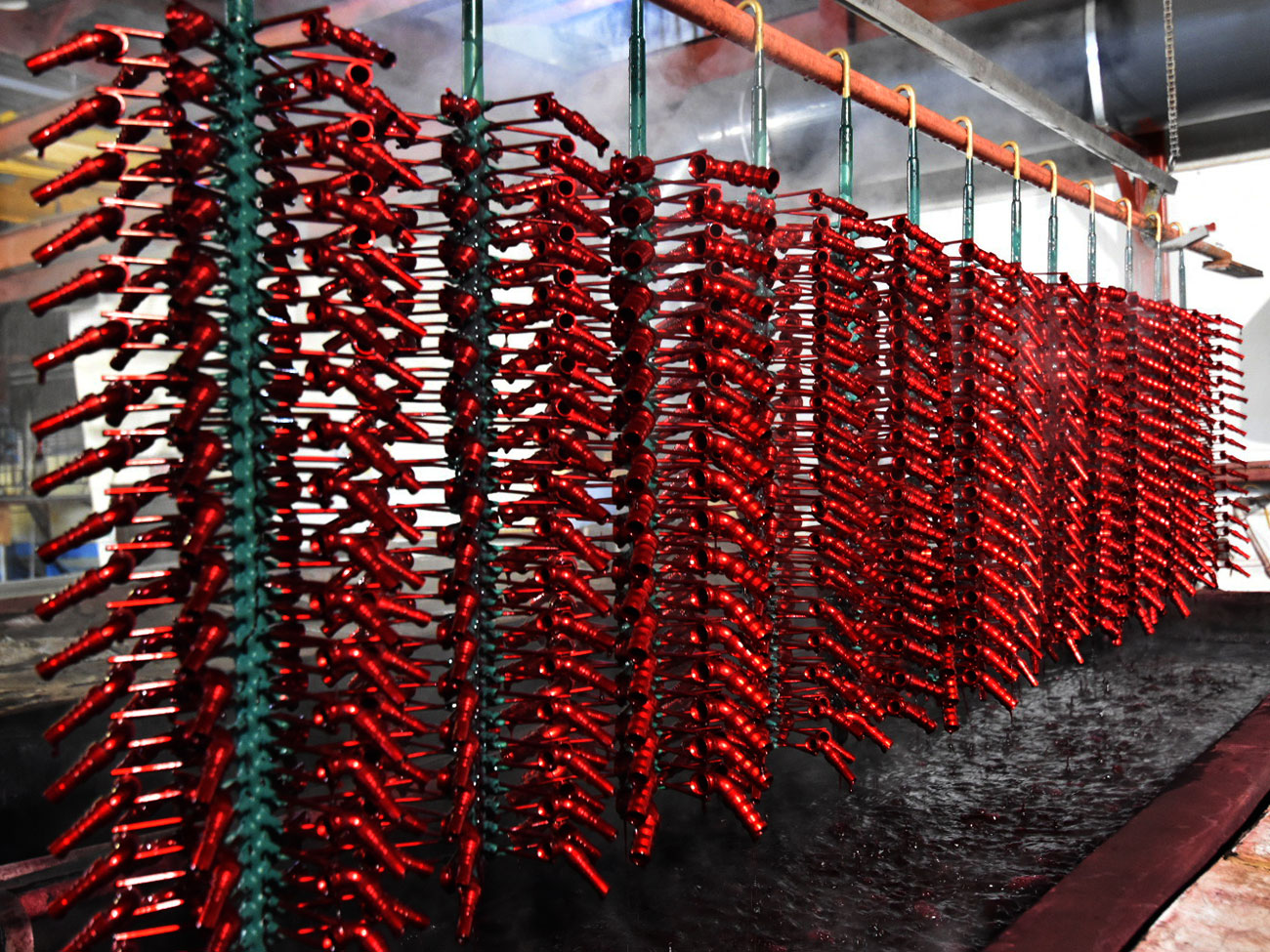

Large tanks for UNIFORM color DYE anodize

Equipped with a variety of large tanks including class II color dye and brite dip

Specialty Hard Anodize and architectural two-step

Includes large tanks for type III hard anodize & architectural two-step anodize

Servicing Southern California and beyond

Four facilities allow for cohesive operations to deliver top quality day after day